This project investigates how a single modular unit can multiply into a flexible design system.

Through joint optimization, pattern exploration, and iterative assembly, the unit adapts into various configurations—planar, folded, and volumetric forms.

The work combines digital fabrication and hands-on prototyping to explore how geometry, material behavior, and connection logic drive form-finding.

- Create a repeatable yet expressive modular unit.

- Develop a joint system balancing bespoke geometry with repeatable fabrication.

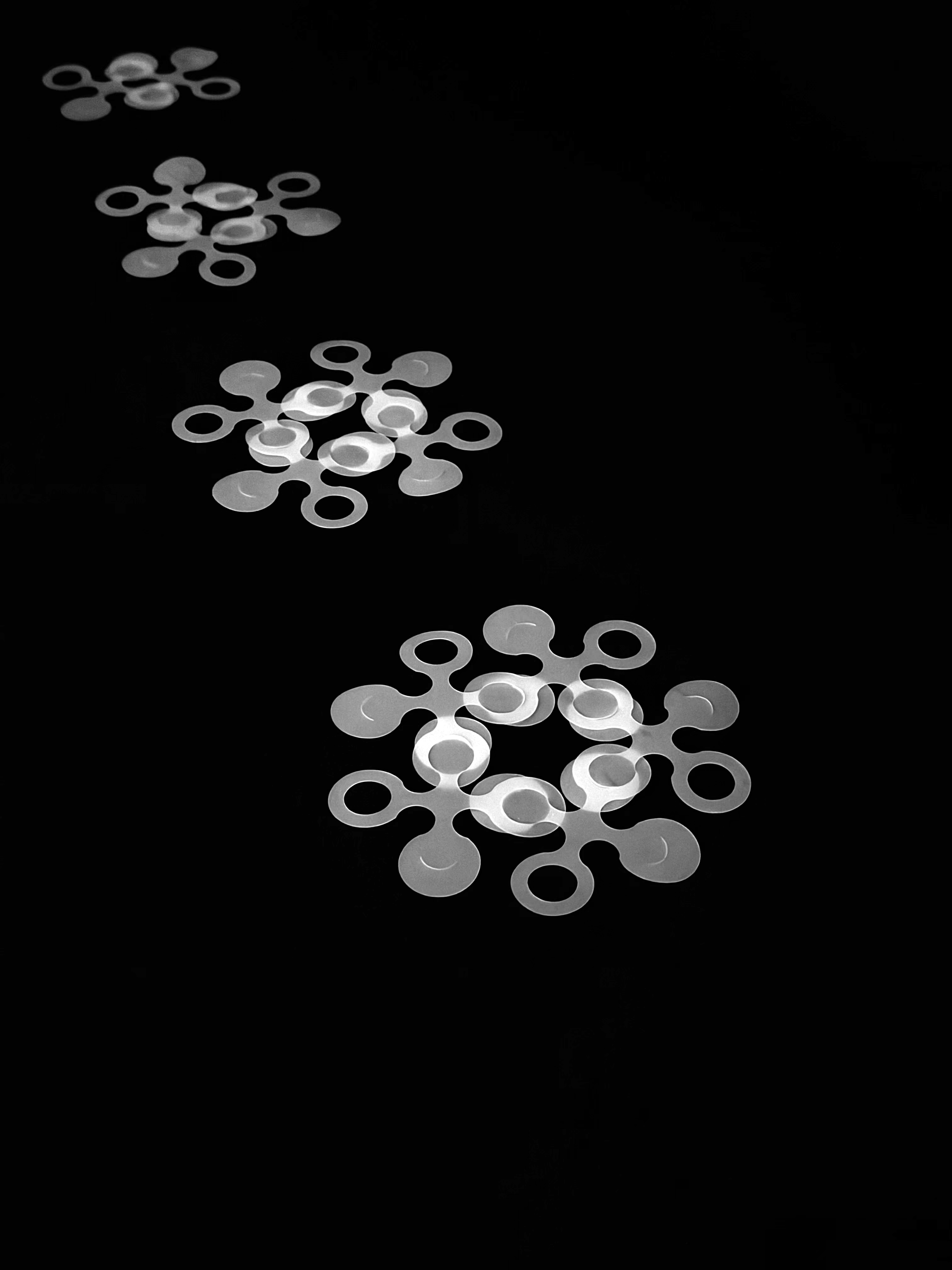

- Explore how modular aggregation produces morphological effects—curvature, density, volume.

- Test feasibility through rapid prototyping and material iteration.

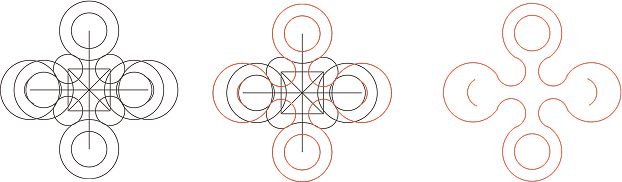

1. Geometry Exploration

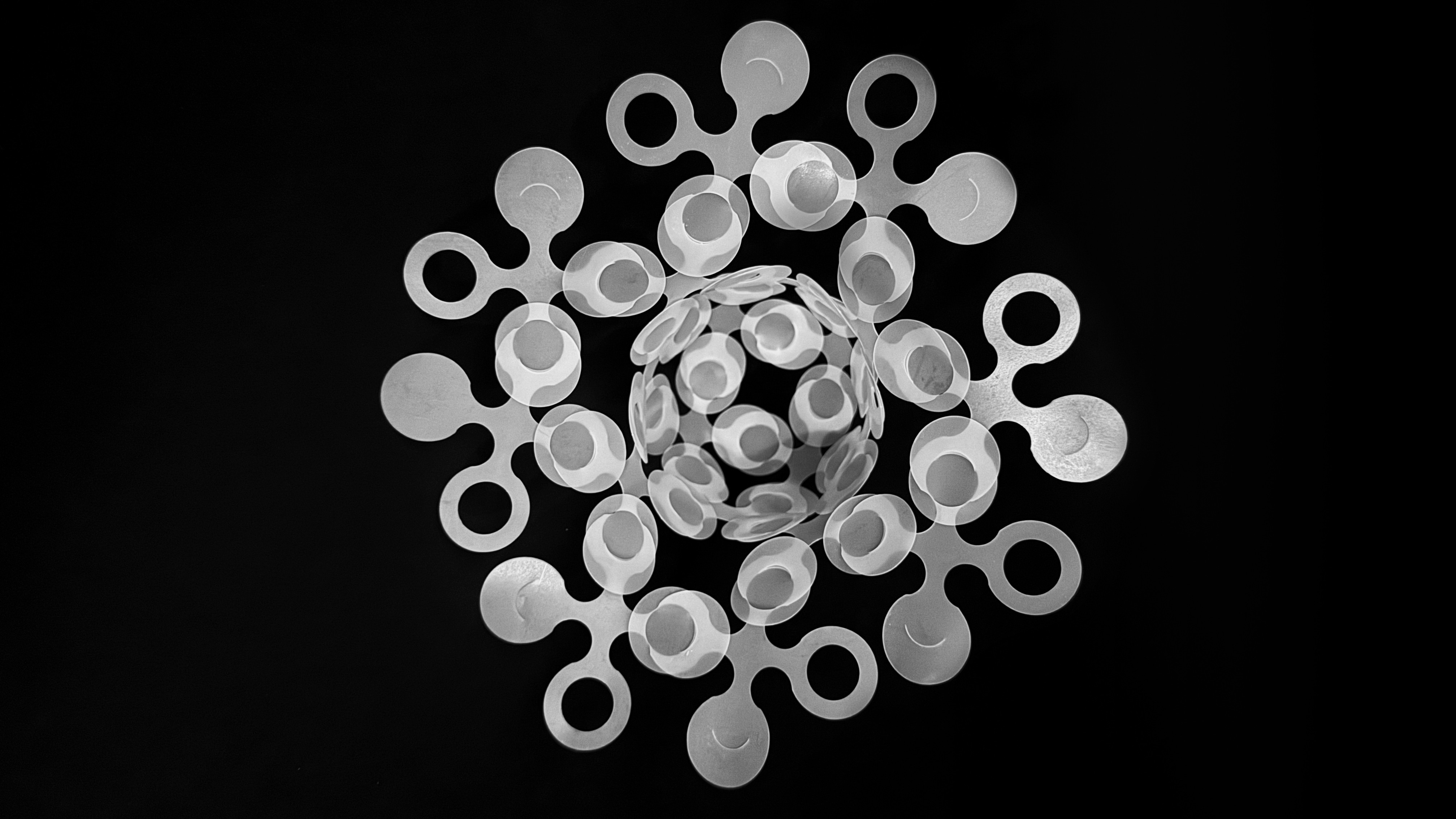

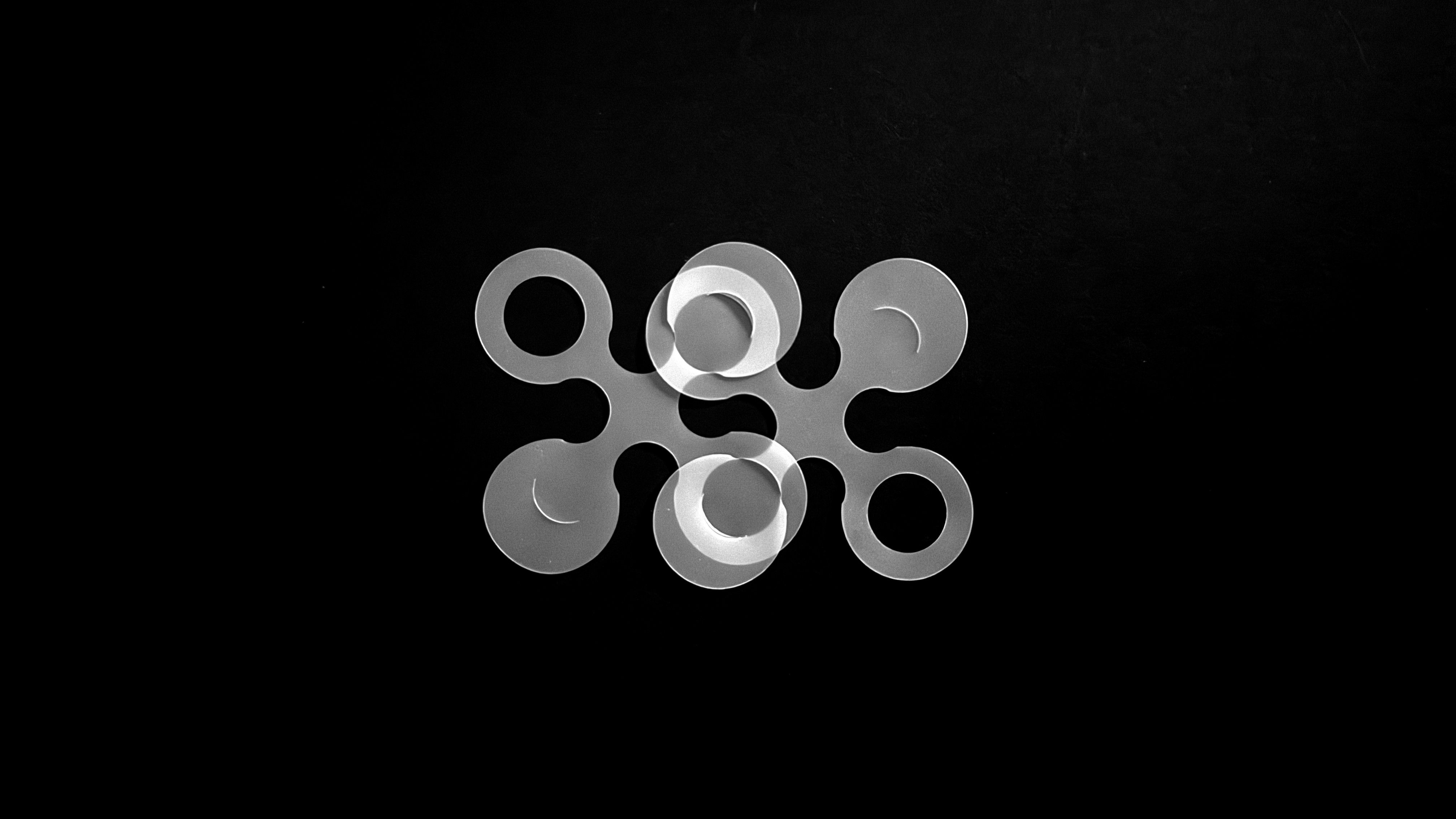

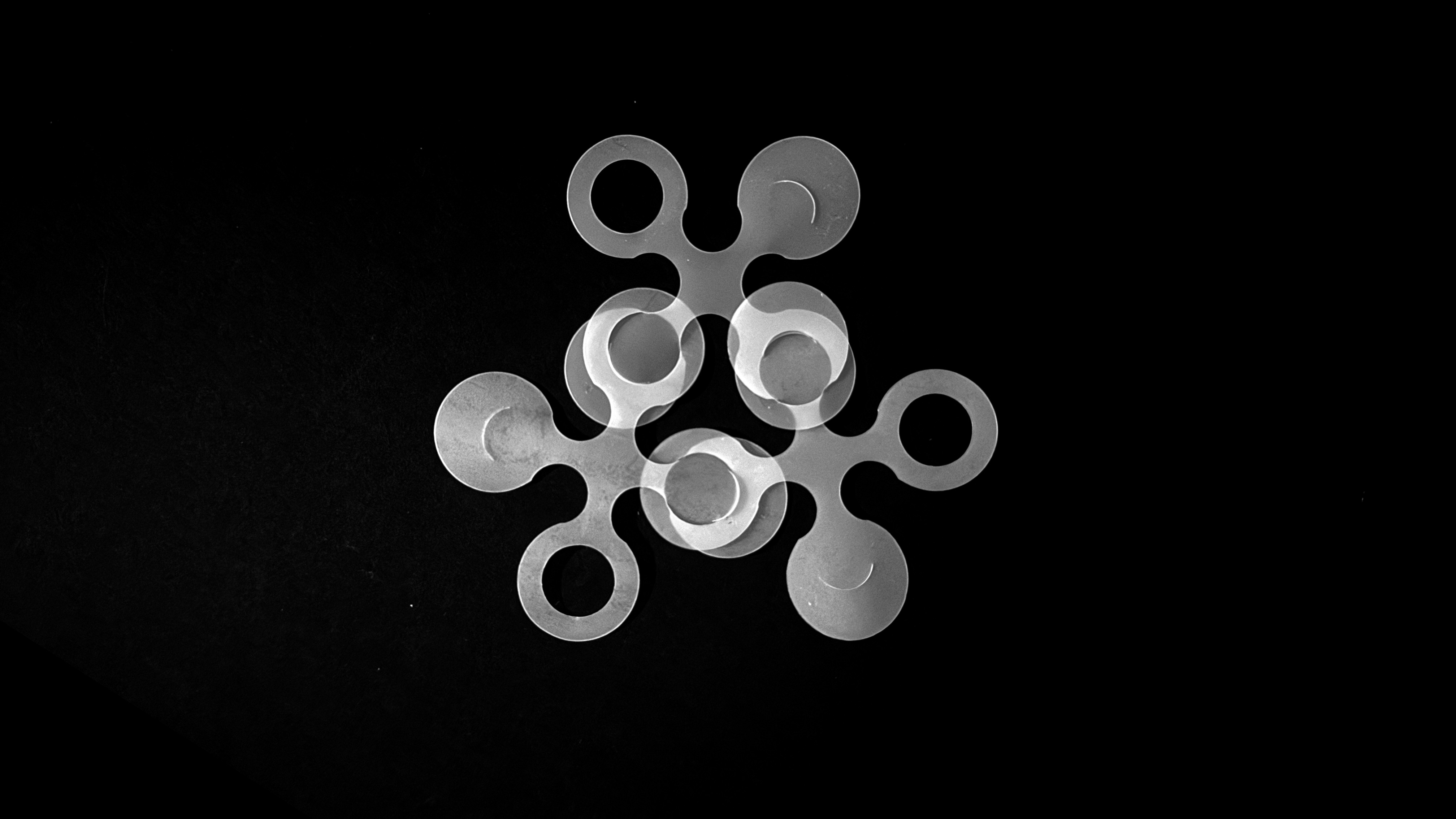

Early sketches and digital drawings investigate circular morphologies and interlocking branches.

Different unit topologies were tested to understand how they aggregate and deform.

2. Geometry Exploration

Early sketches and digital drawings explore circular morphologies and branching connections.

Different unit topologies were tested to understand how they aggregate and deform.

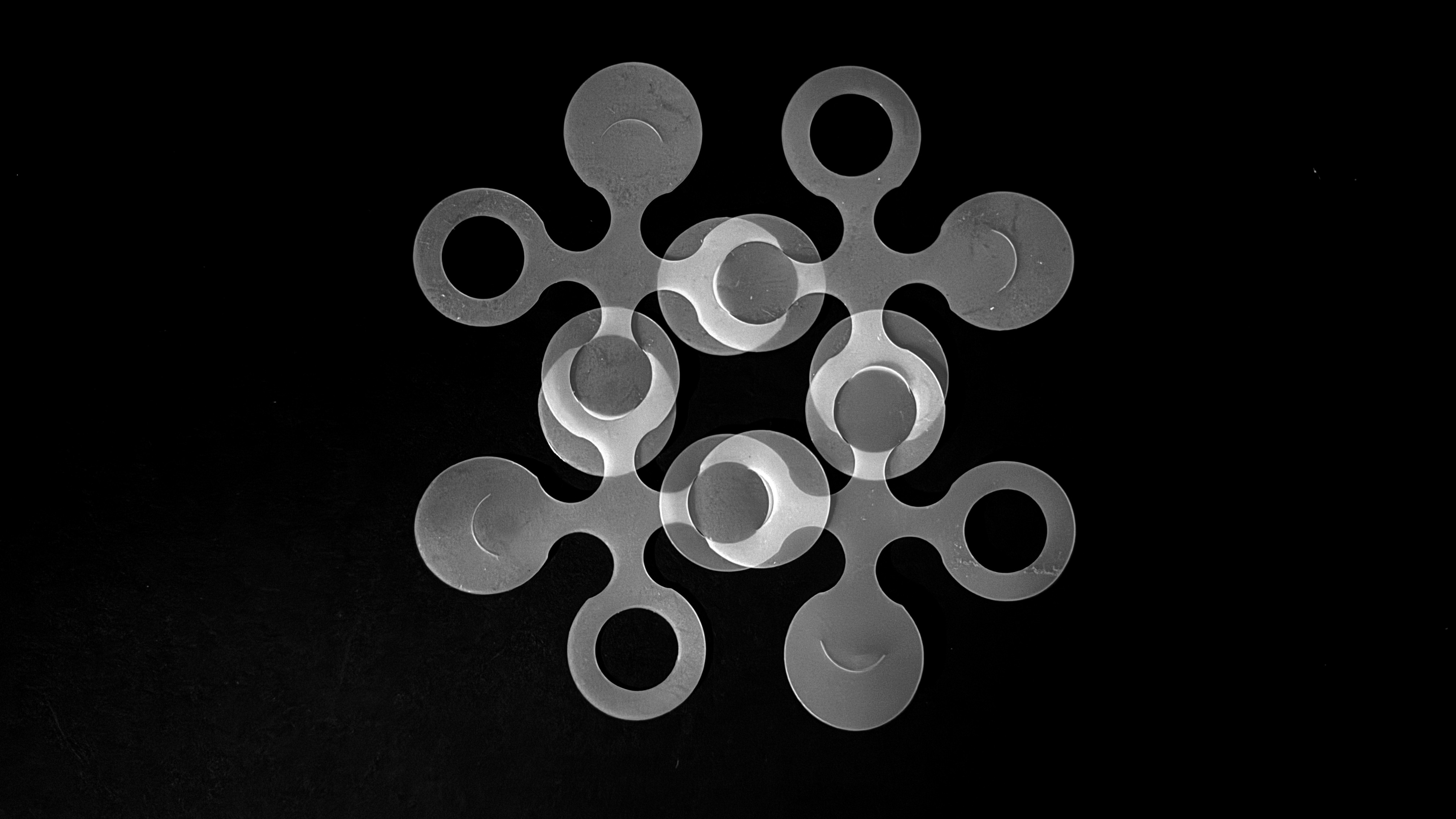

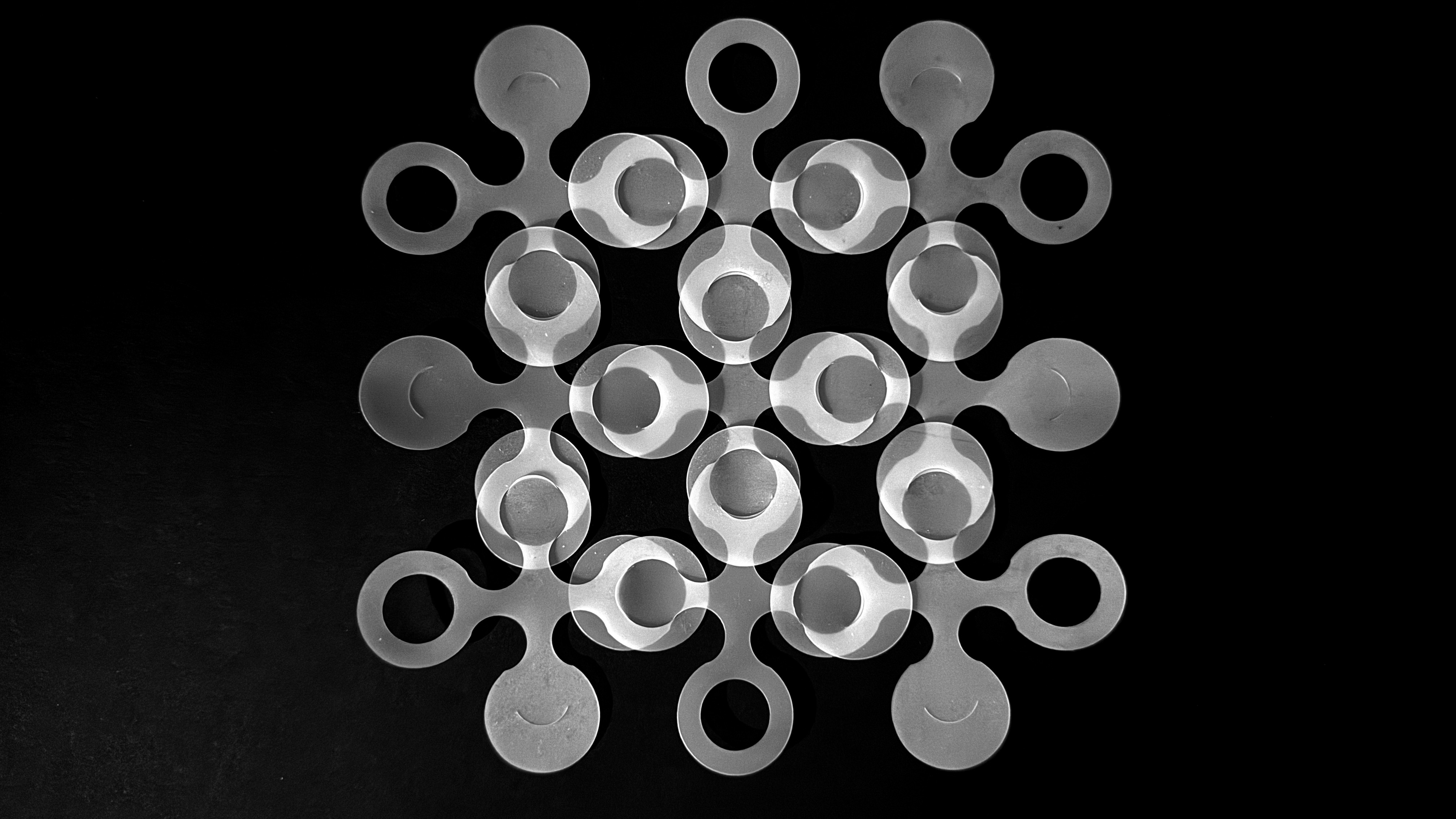

3. Digital Pattern Development

Units were drawn in Illustrator and refined through multiple iterations.

Joint proportions, slot tolerances, and material constraints were optimized through parametric adjustments.

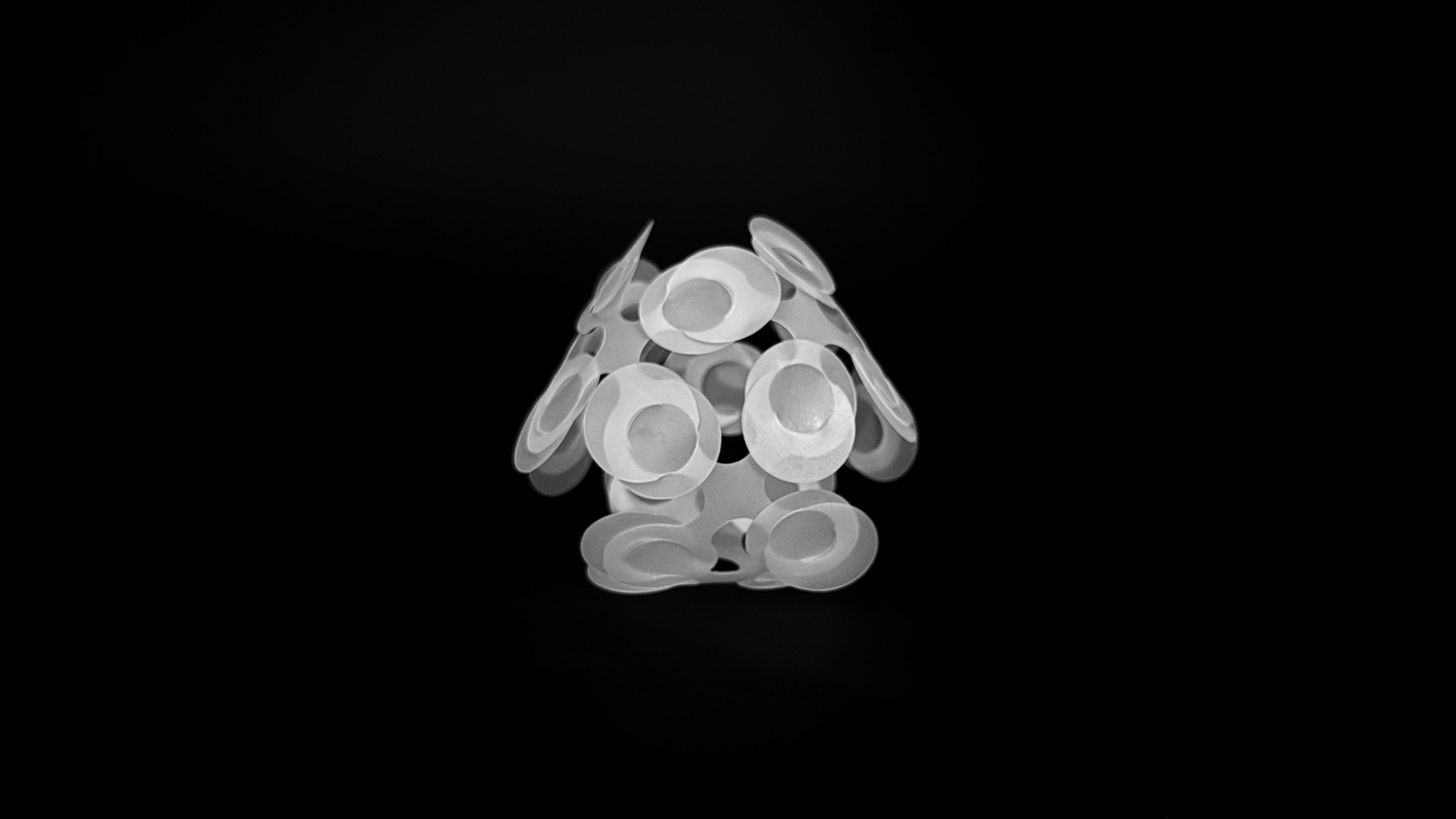

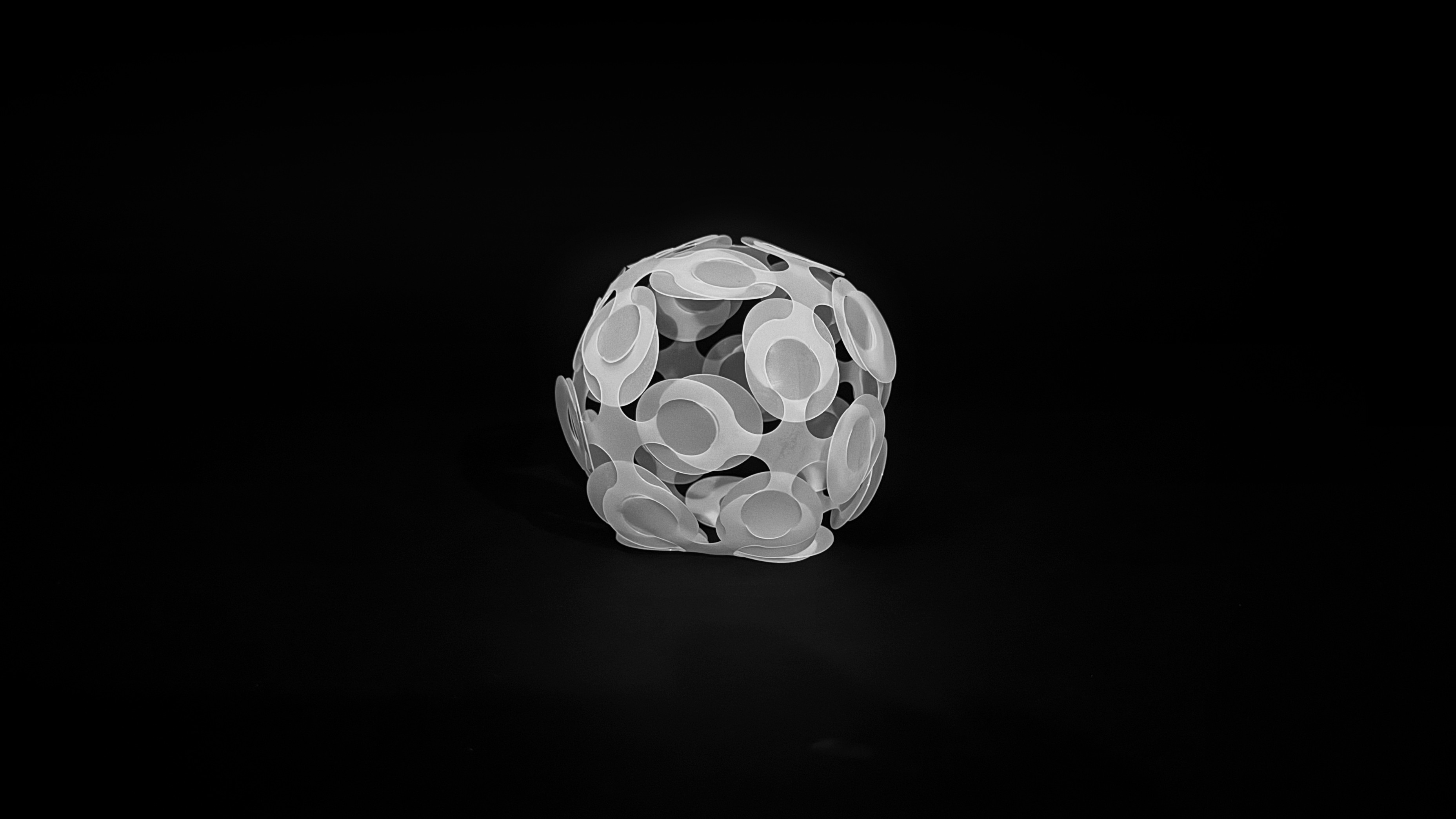

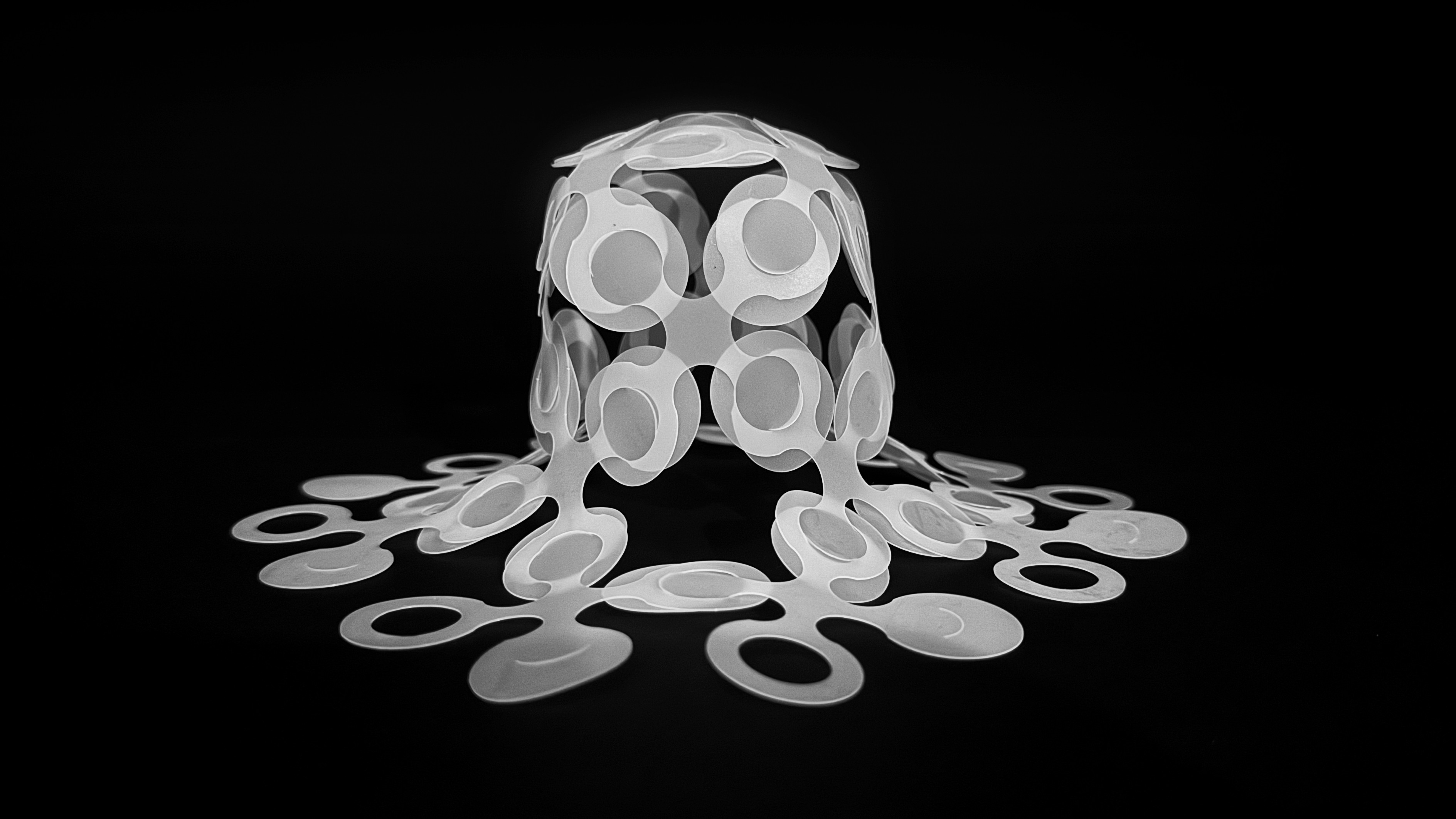

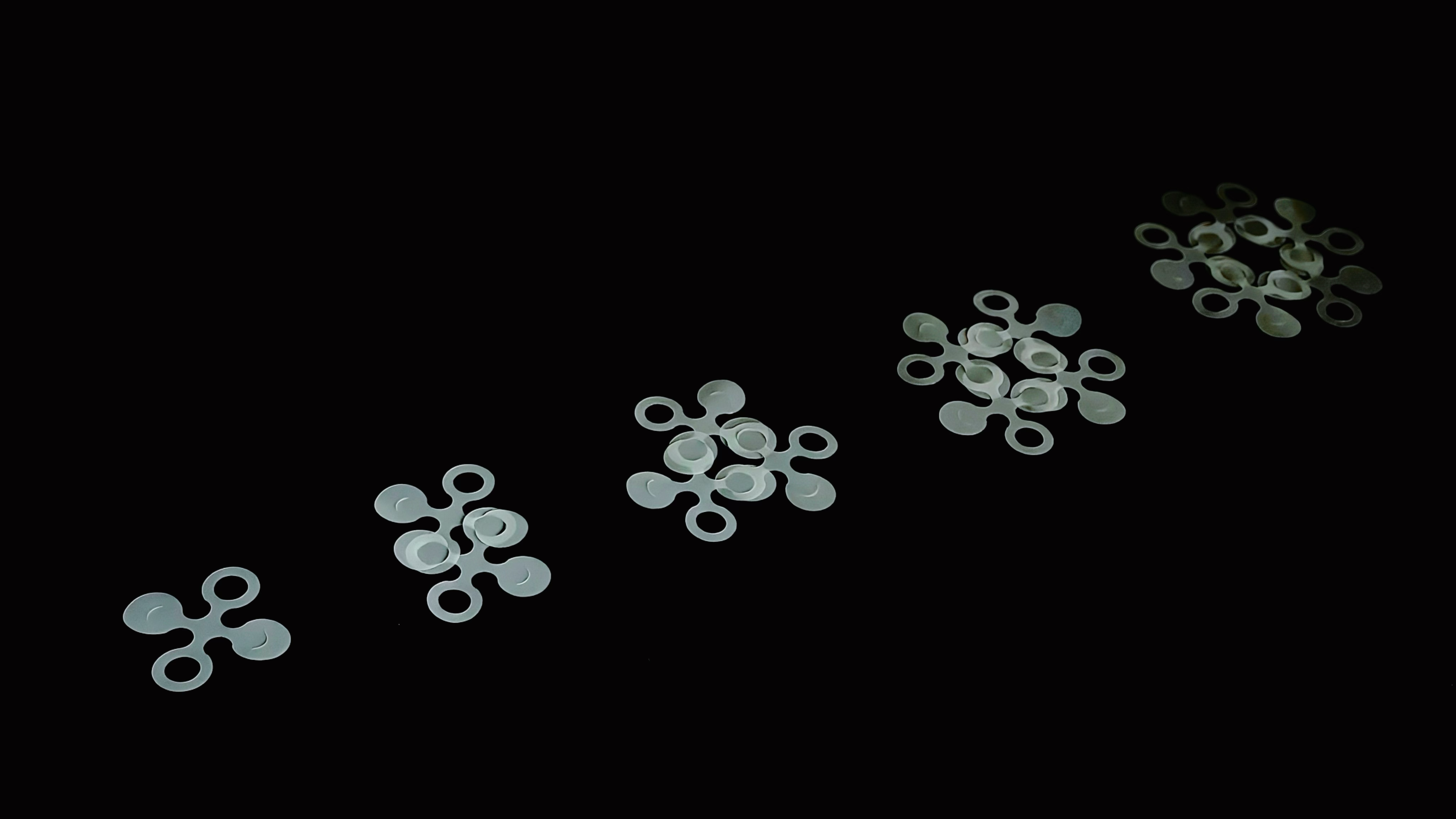

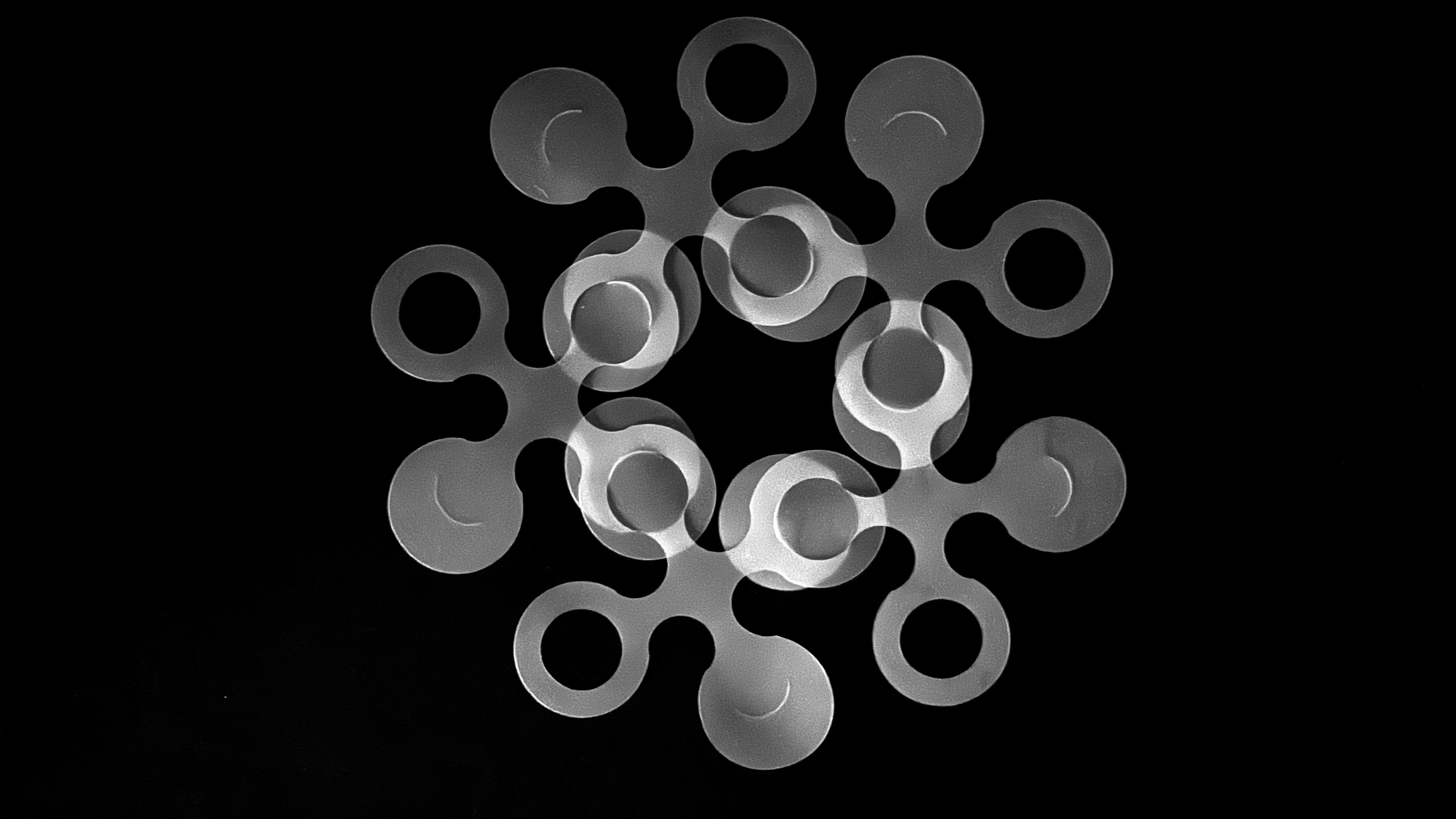

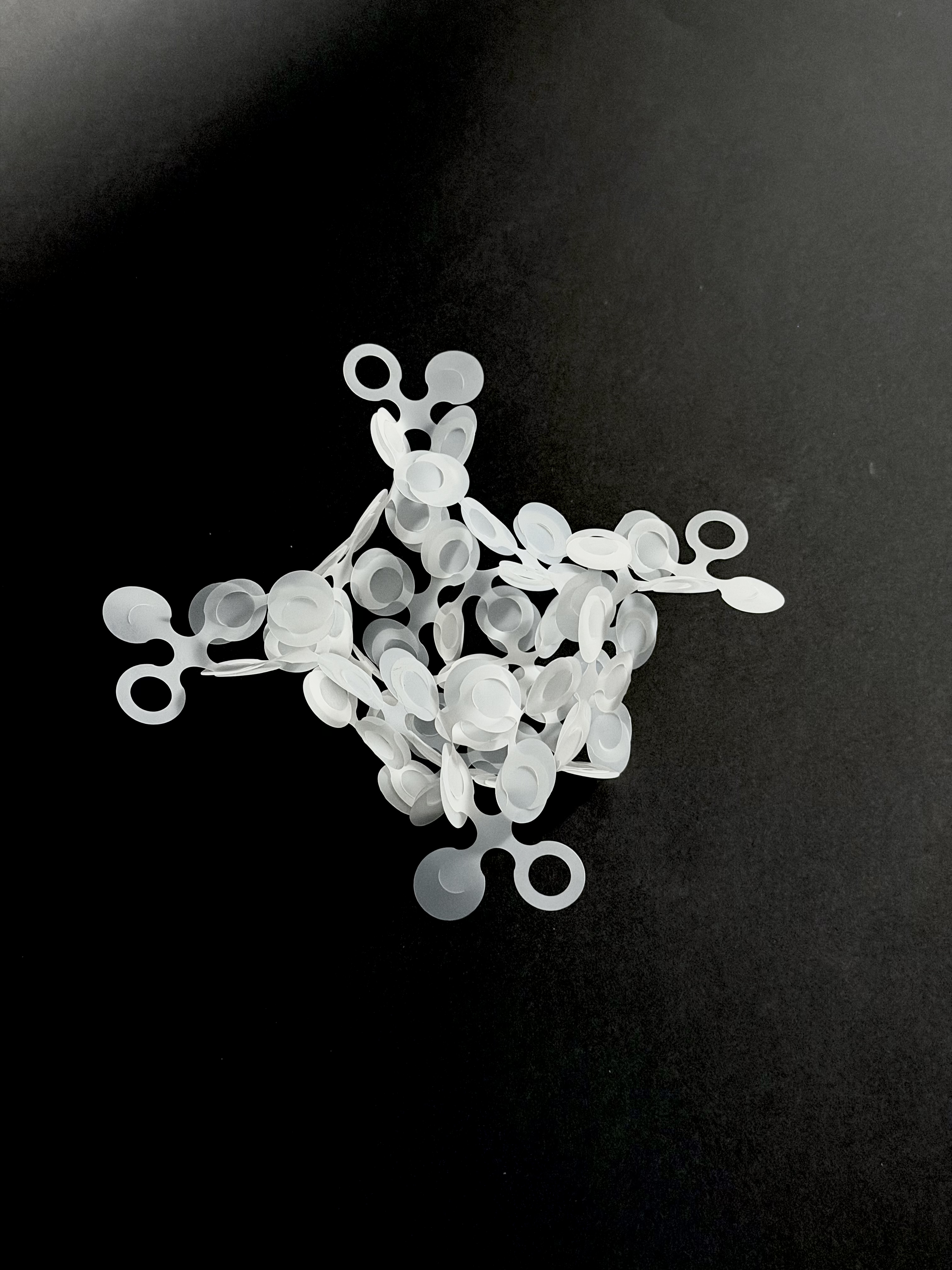

5. Assembly & Form-Finding

Through stacking, layering, and clustering, diverse morphologies emerged:

- planar tessellations

- soft curvature

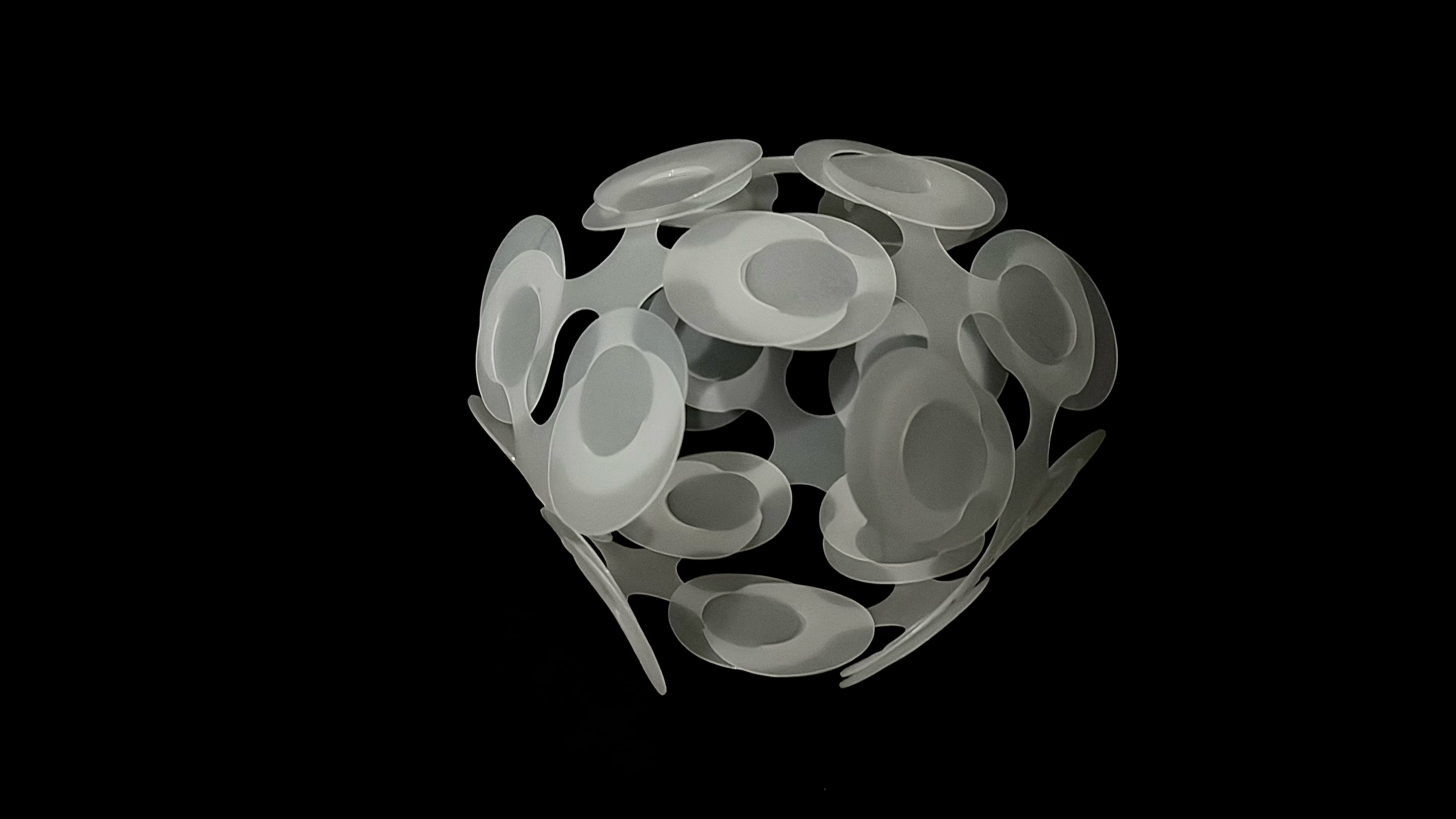

- shell-like enclosures

- volumetric forms wrapping around light sources

The same geometry adapts dramatically depending on how units interact.

6. Morphological Effects / Final Outcomes

- Unit 1–3 → simple planar clusters

- Unit 4–5 → emerging curvature

- Unit 9+ → dense, volumetric shell formations

Under lighting, the surfaces generate layered shadows and nested geometries, enhancing spatial depth and visual density.

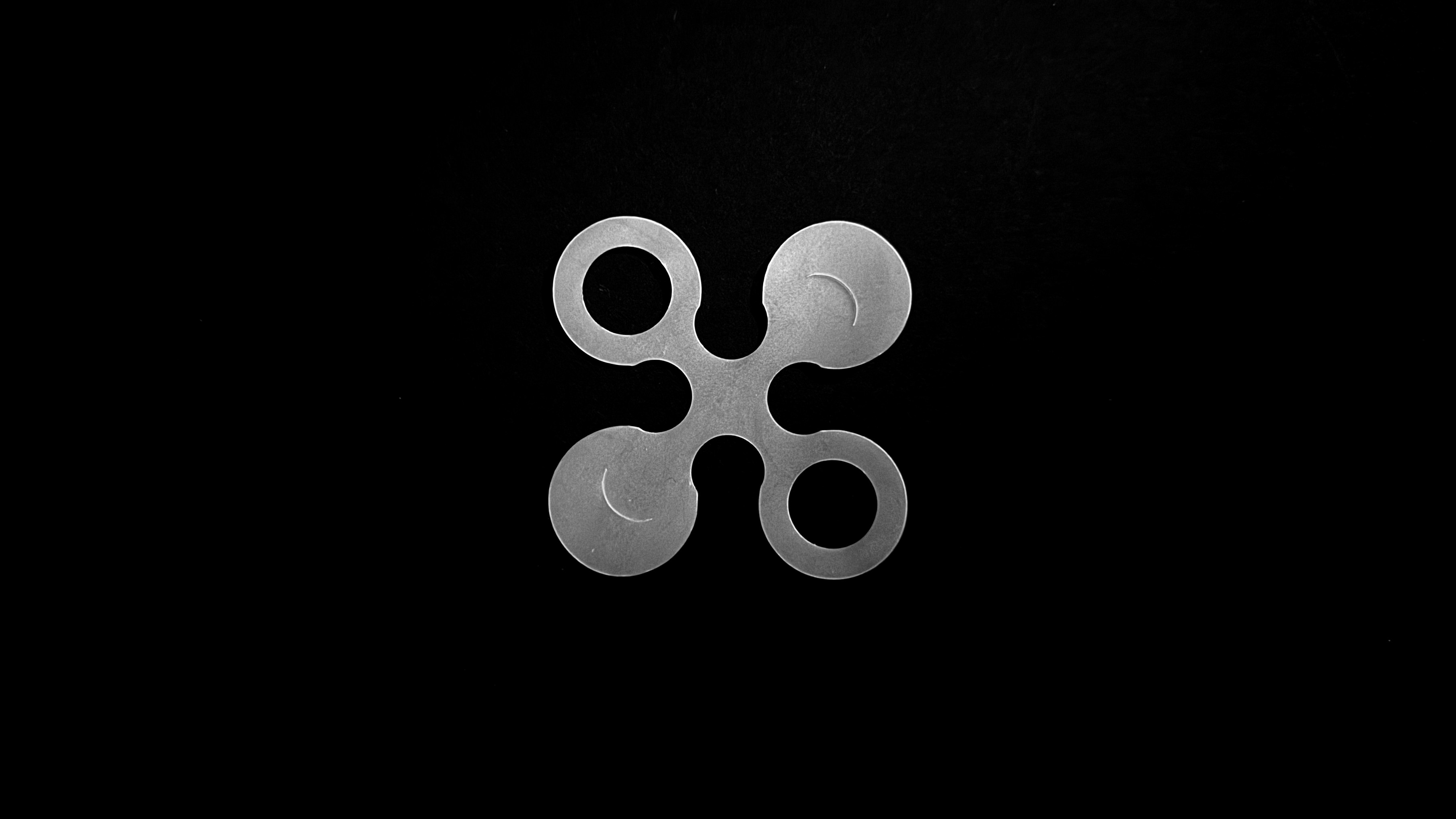

4. Material Experiments & Joint Prototyping

Using Zünd cutting, laser cutting, and occasional 3D printing, a series of physical prototypes evaluated:

- flexibility & bending behavior

- friction-fit strength

- durability across materials

- assembly feasibility and tolerance control

These tests refined the joint logic and verified structural behavior.

The system demonstrates a wide range of expressions:

- Unit 1–3: simple planar clusters

- Unit 4–5: emerging curvature

- Unit 9+: dense structures and volumetric shells

These transformations highlight the adaptability of the modular language.

Under lighting, the unit produces layered shadows and nested geometries.

The modular aggregation interacts with illumination, creating dynamic spatial effects.

- Pattern illustration of modular units

- Material experiments & cutting

- Joint modeling (3D printing if applicable)

- Parts assembly

- Feasibility & structural testing